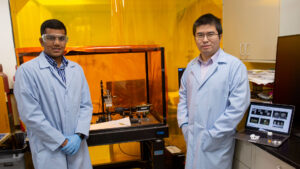

Chayaank Bangalore Ravishankar

Manufacturing engineering

Hometown: Bengaluru, Karnataka, India

Graduation date: Spring 2024

MORE | Spring 2023

3D Printing of Functionalized Piezoelectric Materials for Sensor Applications

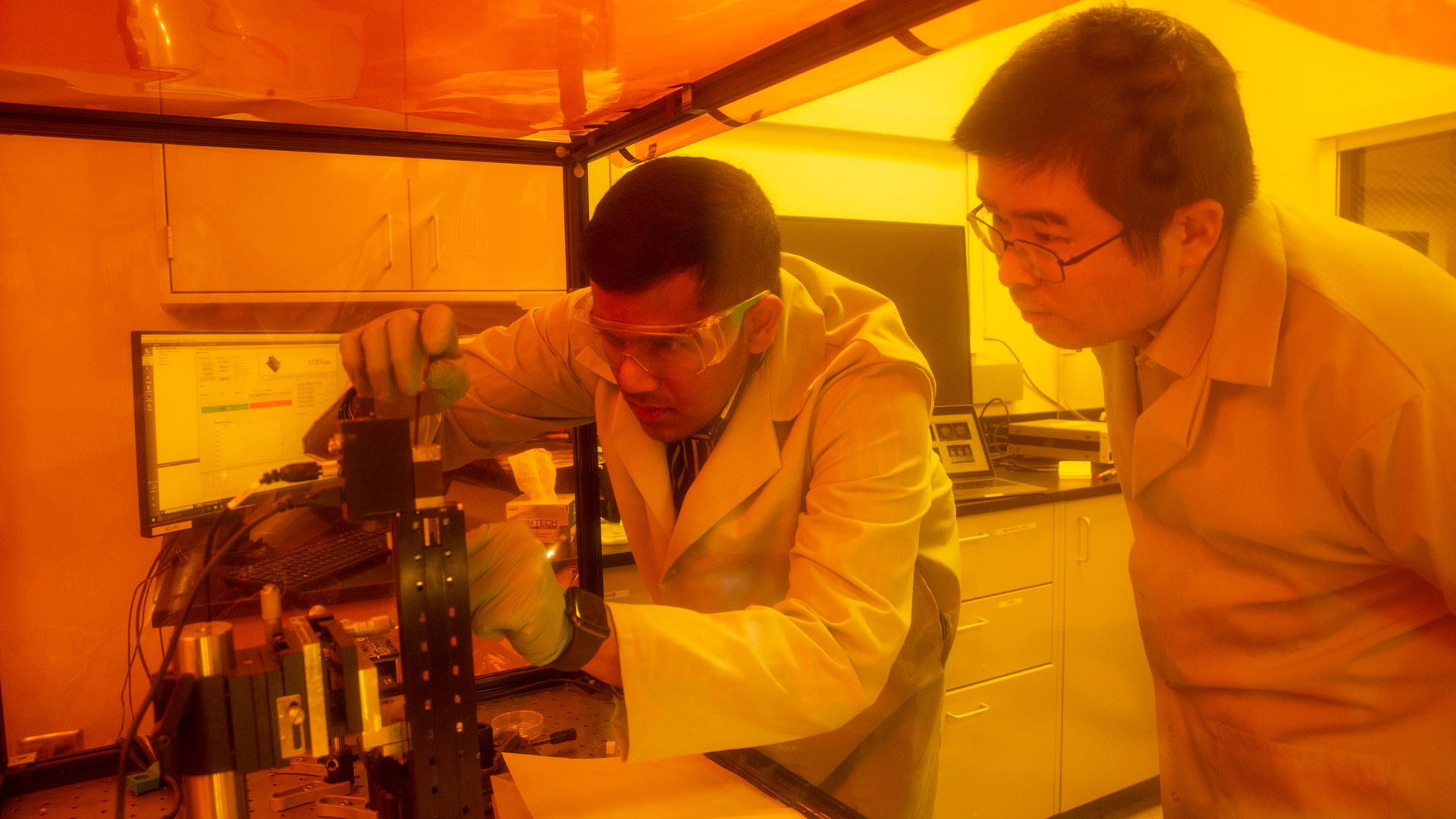

Micro Continuous Liquid Interface Production is a type of 3D printing in which photo-polymerization is used for fusion, which solidifies the resin, resulting in strong objects with a smooth surface finish. By the addition of lead zirconate titanate to functionalize the piezoelectric materials, higher piezoelectric charge constant can be achieved, without harming the mechanical flexibility of the print. This research will focus on the rapid 3D printing of functionalized piezoelectric materials to achieve better characterization, which can further help in the applications of sensors and actuators in the biomedical industry.

Mentor: Xiangfan Chen

Featured project | Spring 2023

Chayaank Bangalore Ravishankar, a manufacturing engineering graduate student, is exploring how piezoelectric materials can improve biomedical sensors and actuators. Piezoelectricity uses tiny crystals to convert physical motion into electric signals, and piezoelectric materials are sensitive enough to detect motion in objects as small as cells. By exploring the use of 3D printing to create piezoelectric materials with his MORE project faculty mentor Xiangfan Chen, an assistant professor of manufacturing engineering, Ravishankar hopes to contribute to their promising future in the biomedical industry.

What made you want to get involved in MORE and the research project you’re working on?

3D printing has always fascinated me by its vast applications in the real world. Getting involved in this program would help me in gaining more knowledge in this field. I chose this project because it was a great opportunity to help the medical industry in getting better results by its complex but fast-paced product outcomes. It would also help me in getting more information about additive manufacturing processes and their benefits.

How will your research project impact the world?

Piezoelectric 3D-printed parts have the potential to play a critical role in sensors where they can pick up slight changes and report them. This is very much needed in the medical industry. They are environmentally friendly and also have many applications for biomedical structures. They are both biocompatible and biodegradable, and have a promising future in the field of sensors and actuators.

What has been your most memorable experience as a student researcher?

I get to learn something new every day in this program. By doing extensive research, we get to know that not every day will be a productive day. Some days we get defects or the yield will not be good. But the “aha!” moment will be the one when we find out the root cause of the defect and rectify it until we get a different defect in the future.

How do you see this experience helping with your career or advanced degree goals?

This project has given me the initial push toward a thesis-based degree, and also makes a great impact on my resume. To land a job in any industry’s research and development sector, companies will ask for prior experience and results that have made an impact, which can be gained through opportunities like MORE.

Why should other students get involved in MORE?

MORE projects are the best stepping stones toward research as the university provides students with an enormous amount of resources and also funds to get the required raw materials for projects. Students will have ample time to study previous papers about their research where they can gain in-depth knowledge about their field and then get hands-on experience in using the university laboratories’ state-of-the-art machines. Even students without prior experience in doing research will get a chance to work under mentors that have real-life experience of what happens in the research world.